Three Centuries Of Door Hardware

By: Sven Kraumanis – owner/operator Legacy Vintage Building Materials & Antiques

The entry door is the portal to a man’s castle. It defines the boundary between public and private. It is the front line in the battles between victims and perpetrators, haves and the have-nots, good guys and bad guys, the authorities and fugitives, incumbents and rebels, forces of light and darkness, emancipators and evildoers. Its décor distinguishes the occupant from “the Joneses”. As such, the history of the door’s latches and locks in many ways portrays society’s evolution- regardless of which side of the door you are on.

The entry door is the portal to a man’s castle. It defines the boundary between public and private. It is the front line in the battles between victims and perpetrators, haves and the have-nots, good guys and bad guys, the authorities and fugitives, incumbents and rebels, forces of light and darkness, emancipators and evildoers. Its décor distinguishes the occupant from “the Joneses”. As such, the history of the door’s latches and locks in many ways portrays society’s evolution- regardless of which side of the door you are on.

Effective locking of a door can be accomplished by a simple wooden bar across its inside dropped into open wall brackets. This warehouse-grade technique has been in use for centuries and is still in use today. Locking is a usually a modest aspect of door fastening, unless formidable power, as exhibited by yawning bank vaults, is part of the deterrent. Locking devices are by nature practical in their design responding only to the ingenuity or might of the guy on the outside of the door. Locking devices have enjoyed only three basic upgrades in as many centuries.

Latching is another story. If period architecture is a fashion show, hardware provides the accessories and door latches are the jewelry. Latches certainly have a practical purpose. However as we pursue the development of their functionality in the context of New World history we’ll linger in a century of whimsical anvil artistry, marvel for a century at artisans’ ingenuity, and languish for decades in a golden era before the fall.

1640 -1740 Handcrafted Latches and Anvil Artistry

Most of us ignore the significance of the blacksmith’s role in pioneer communities with twenty-first century smugness- if we’ve given it any thought at all. Some of us remain unmoved by his function even after our second or third tour of a smithy’s typical 18th century workshop- as interpreted by government-hired subcontracted historians at your local heavily tax-subsidized and volunteer-staffed pioneer village. These presentations are appropriately sanitized to suit an audience of cubs and brownies but barely hint at the esteem due to an essential pillar of early communities. The smithy’s trade in fact had a pivotal role in the making of New World history.

It was the blacksmith that chanced upon the unique properties of iron that led to the making of the compass with all its ensuing navigational possibilities. His fastenings bound together the ships that discovered new worlds and banded the staves of barrels that provided salted pork and fresh water enough for ocean crossings. His metallurgy developed alloys with hardness and malleability suitable for weapons, tools, agricultural implements, kitchen utensils, and builder’s hardware that enabled pilgrims to settle the New World. He often had to keep accounts and as a result had a rudimentary grasp of the three R’s. These trade requisites thus made him better educated than most common folks and the practical and useful results of his labour put him in higher regard amongst his rural neighbours than other professionals such as bankers and lawyers.

Early blacksmiths could not keep up with the demand for hardware in the rapidly expanding colonies. Roads and transportation systems didn’t exist to effectively distribute the wrought iron brought over as ballast in trade ships. Also, brass foundries beyond England’s shores were outlawed by her Acts of Trade designed to protect the industry in Birmingham. The undersupplied demand meant approximately 85 % of 17th and 18th century New World hardware had to be imported. It was predominately British but mixed in were with French, Italian, Spanish, Dutch and German goods. Why does our tale begin in the 1640’s?

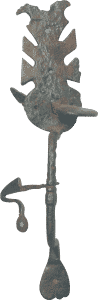

The first iron works in America was established in Saugus Massachusetts in 1646. Blacksmiths brought to the New World their time–tested styles and applied them to door hardware. The thumb latch was the solution of choice. The thumb latch consists of five parts: the handle, thumb piece, latch bar, guard and striker (or keeper). Occasionally a pendulum styled piece of metal was affixed above the latch bar which when swung down to impede the lifting of the latch bar would act as a lock. However the locking of the door was typically carried out by a rudimentary plate lock (see figure 1). This was essentially a slide bolt mounted on the inside of the door. Through a hole in the door leading to a patterned keyway into the case- unique to keys also made by the locksmith- a key holder can now, from outside the door, throw the bolt comprising the lock. This “warded” case was the first advancement for the slide bolt (see figure 2).

|

|

Figure 2. |

The artistry was in the latch. In an early 19th century treatise “English Metalwork”, William Twopenny (1797–1893) coined the names “Suffolk” and “Norfolk” to describe the two most common styles of thumb latches. The Suffolk has no back plate (see figure 3). It appears in many patterns such as Tulip, Arrowhead, Ball and Spear, Swordfish, Ball Crescent and Spear, Pine tree, Tobacco Leaf, Bean, Heart, Cocks head, Lyre, fleur de lis and several geographically unique styles.

|

Figure 3. |

Figure 4. |

The Norfolk also appears in several designs, always distinguished by the presence of a back plate (see figure 4). Blacksmiths artfully carried the latch design themes into other hardware produced at the time, notably hinges, hasps and wagon parts. Because of its scarcity this early hardware is extremely collectible. In May of 2005 a Pennsylvanian auction house sold James Sorber’s life long collection of early forged hardware and established benchmark prices for this aspect of pilgrim talent. Many dozens of thumb latches each sold in the $300 to $400 USD dollar range with unique pieces selling in the $1000’s and the most sought after thumb latch fetching $10,350 USD. Mass produced thumb latches remain in use today, available at your corner hardware store in the $5.00 range.

1740- 1840 The Early Locks and Artisan Ingenuity

Figure 5.

Migration to Canada from the south was prolific as Americans enjoyed Canada’s abundant and fertile lands. During the 1780’s seven thousand revolutionary war refugees (United Empire Loyalists) arrived. These U.E.Ls came with style and many built two storey “Georgians” (with the façade typically displaying five windows over a row of four windows and a centered door.) These homes topped the pioneer’s housing transition and as a result hardware began its own journey of sophistication. The first move away from the thumb latch was the plate latch (see figure 5). Also called square, keyhole, spring, or wishbone latches (because of the shapes of the backing plates or the brass spring) these latches retain the thumb latch concept of the latch bar and strike but mount the latch bar and guard on a plate that can then be readily installed as one piece. The true innovation was the use of knobs to lift the latch bar when the knobs were rotated. The knobs were tiny by any standard, always brass and usually round or slightly oblong. Another novelty was the occasional incorporation of a privacy slide bolt on the same plate as the latch.

Figure 6.

What is a box lock? (also known as Pennsylvanian, Moravian, or Dutch elbow locks –see figure 6) Envision an enormous, iron-encased plate latch complete with an integral keyed lock and you’ll have entry door hardware with the requisite sturdiness and grandeur to suit the needs of the era. To raise the latch bar against the stiff springs the use of lever handles instead of knobs was a common solution. Since all locks and latches were surface mounted on the interior of the door, buffing and brass trimmings inevitably followed. Some blacksmiths now exclusively made locks. Because they polished their work they were known as whitesmiths. They quickly developed tool and die maker’s skills extending to lathe work, spring tempering, and the manufacture of rivets and screws.

The housing of both the latch and lock functions in one device of course became standard and strikes were also adapted for this a duplex function. Plate latches appeared in many countries and in many shapes but are tiny cousins to the box locks also prevalent during this period (1750-1790). “Lock” hereafter often will describe a device that combines both latching and locking functions.

Figure 7.

Blacksmiths and whitesmiths could not meet the demand. There were no reliable and affordable sources of wrought iron in Upper Canada because of out of date technology and a lack of cheap fuel. Concurrently, immigrants brought with them high quality and inexpensive metal products from England and the North American States. A common door latch in use was one patented by the Englishman John Carpenter in 1820 (see figure 7). He never made one himself but granted twenty licenses for the fabrication of the Carpenter Box Lock. The latch bar continued to function with the awkward up and down movement and warded keyways were replaced by an internal ward which the key had to displace before any bolt movement could occur. The advent of box locks and the diminished residential use of thumb latches is for some the demarcation line for “early” hardware.

The War of 1812 and the trade blockade accelerated the self-sufficiency of the settlements in the new world. American brass foundries were quickly established and in 1831 Frederick T. Stanley set up a factory in Connecticut dedicated solely to the manufacture of locks. As an additional consequence of the war, hordes of United Empire Loyalists and Britons came to Upper Canada after American invasions at both ends of Lake Ontario had been repelled. Upper Canada had a population of approximately 100,000 when the U.S. declared war on Great Britain, 80% of which comprised U.E.Ls.

Figure 8.

1840 -1940 The Golden Era

The year 1840 is the patent date of the first patented cast iron thumb latch (see figure 8). This event heralds the end of handcrafted locks. Pouring iron into moulds enabled mass production of these latches. This period is generally recognized as the dawn of the Industrial Revolution and birth of the economics of scale. The larger the operation the more profitable it could be. A similar evolution was evident in many aspects of hardware production. Square iron nails were each hand cut and faceted by a blacksmith using chisels until 1790. Thereafter shearing machines cut them until they were made from wire in 1851 and steel 1883. Similarly, screws were hand cut with filed threads until 1810 after which they were punched from steel.

In 1851John Pepper patented “Mineral Knobs” now generally known as porcelain knobs (white, black and Bennington brown- see figure 9) to supplement the prevalent use of wooden, and pressed or mercury glass knobs. During the next fifty years hundreds of patents were issued to famous names such as Linus Yale, Phillip Corbin, Walter Schlage, Sargent & Co., Mallory & Wheeler and Russell & Erwin to name a few. The surface mounted cast iron box lock or “rim lock” became a Canadian standard (see figure 9). Dynamite was invented in 1867 adding a new dimension to security issues. The British designed a widely accepted “mortised” case that was buried in the edge of the door- a location requiring the latch to retract and release into a strike plate instead of having to lift and drop onto the strike (see figure 10). Lever tumblers replaced heavy wards and upgraded the security of keyed locks. Then in a final 1865 refinement to keyed locks Linus Yale fitted them with cylindrical keyways in which delicate spring loaded “pin-tumblers” had to conform to an exactly contoured key for the key to function.

Figure 9. |

Figure 10. |

Undoubtedly the most apparent advance for hardware during this period was in the realm of aesthetics. It flows from a patent granted to the Metallic Compression Casting Company (MCCC) of Boston in1869. When MCCC introduced its hitherto unparalleled and exquisitely designed bronze castings Russell &Erwin (R&E) was using 91/2 tons of iron per day in the manufacture of its hardware. Not to be outdone, R&E bought MCCC, commissioned more artists and spurred on by the wealth in circulation during those expansive times led the decorative hardware industry through its high-water years. The style that launched the decorative frenzy was called Eastlake- distinguished by bronze fittings crisply incised with geometric patterns, three-dimensional figurals and later, Japanese and mid-eastern motifs (see figure 10). Lion and dog doorknobs designed by MCCC’s Ludwig Kreuzinger are each valued by today’s collectors in excess of $2000 USD. The heyday lasted for half a century. Records indicate that in1897 New York State alone produced 30,000 doors per day. They all needed hardware.

The industrialization of civilizations alters their social order. The middle class, consisting largely of artisans, farmers and merchants is vastly diminished as mass production replaces individual handwork and the appeal of steady jobs and abundant material goods draws people to the manufacturing centres. In1879 Sir John A MacDonald’s protectionist National Policy encouraged “local initiative”. This undermined local self- sufficiency and in the 1890’s moved communities to mass consumer activity as industrialists and investors sought ever bigger markets. Growth momentum shifted from country to city and rural depopulation began. From 1840 to1891 the population of southern Ontario grew from 500,000 to 2,000,000. Cities held 25% of the population. By 1908 the cities held 50% and today they hold 80% of our population. Canadian enterprises like the Gurney, Peterborough and Belleville lock companies entered the marketplace only to fold or be taken over by bigger competitors. This is the Darwinian aspect of industrialization: a predominately middle class erodes and is replaced by untrained workers and wealthy industrialists while amongst competing companies only the strongest survive. Large merchants swallow small merchants. By the turn of the century competing hardware companies were under growing pressure to bid large orders but with a sharp pencil. This of course resulted in a compromise of quality. After the Eastlake Style (1865-1890) ran its course industrial designers created patterns reflecting successive prevailing tastes. They successfully outfitted and beautifully adorned the built heritage during our Victorian (1880-1915), Arts and Crafts (1895-1920) and Art Deco (1925-1950) periods (see figure 11).

Figure 11.

The economic realities of depression and war weighed heavily on the industrialized world and left no industry unscathed. If the Arts and Crafts period was a look back with a yearning for simpler times, then so too are all the Revival Styles (see figure 11-Gothic, Tudor, Spanish, Colonial etc.,) a look back.

The difference is that the Arts and Crafts era grew from a philosophy about life after the excesses of the Victorian era whereas “Revival Style” is a marketing ploy. Arts & Crafts was a period that Stickley, Morris, Tiffany & Wright immortalized with their work. Revival Style is a creation of developers whose interpretations of past designs lose meaning with each reproduction

There is tremendous value in the styles of times gone by because they reflect societies’ values, if you look hard enough. What say you then of hardware generated by an industry bereft of novel ideas, driven by the need to inexpensively mass produce for a society constructing approximately 175,000 dwellings a year, marketing in large measure to a benignly mediocre culture that accepts quantity as a substitute for quality and equates price with value?

Is it any wonder that antique hardware is valued as an investment?

Legacy Vintage

Legacy Vintage